Troubleshooting

- NITRILE RUBBER PACKING

-

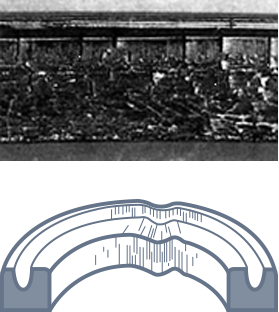

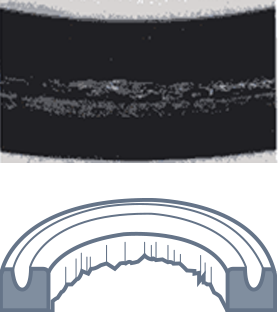

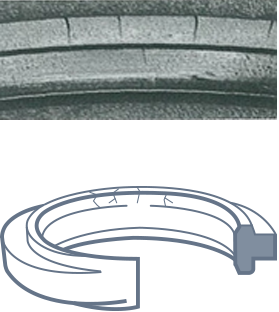

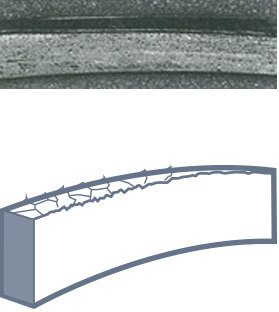

Case Status Reason Response Deterioration

(劣化)Entire operation surface is hardened. Sheenful surface is already cracked or cracked by pressing with a finger.

Heat generation because of high speed or excessive internal pressure In the case of piston, change to SPG and SPGW. In the case of load, use back up ring. Entire packing is hardened. There is a huge lip dent. Cracked if bent with a finger

Oil temperature is high. Lower oil temperature or change to heat-resistive material(fluorine rubber ). Effect of oil

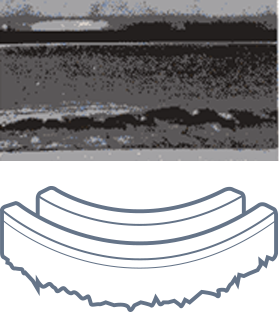

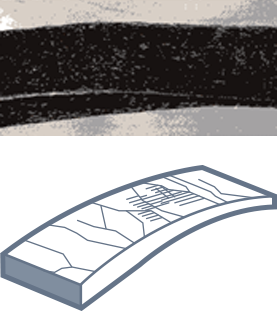

-Inconsistence between oil and rubber material -Oil deteriorationChange to a rubber material with strong oil-resistance. Change to new oil. Small cracks across the whole packing surface

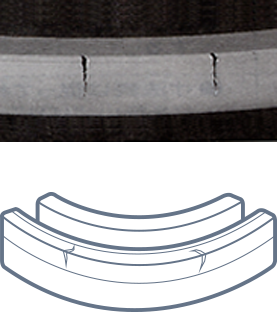

Ozone crack by leaving packing in the atmosphere for a long time Do not open the packing unnecessarily. Keep it sealed in a cool and dark place. Ozone crack by leaving while being mounted in piston Do not leave in piston. Assemble into cylinder as soon as possible. Swelling Softened generally

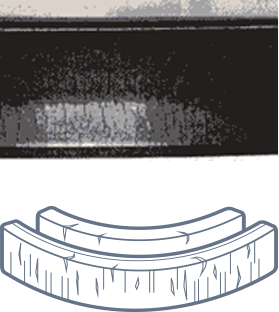

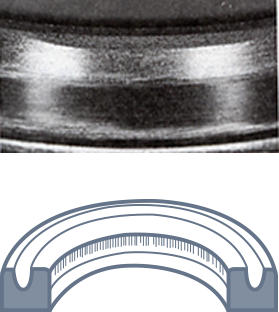

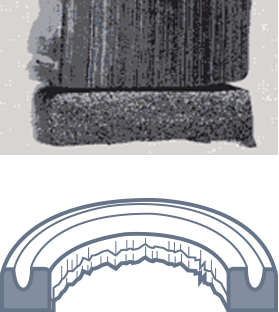

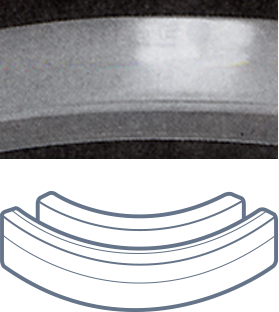

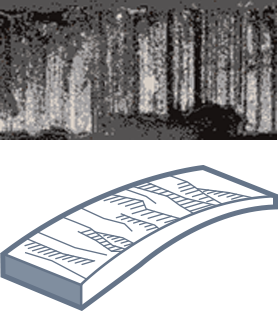

Inconsistence between oil and rubber material Change to a rubber material with strong oil-resistance. Effect of cleaning liquid Change cleaning liquid. Remove cleaning liquid. Abrasion Operation surface is sheenful and abraded on the mirror side.

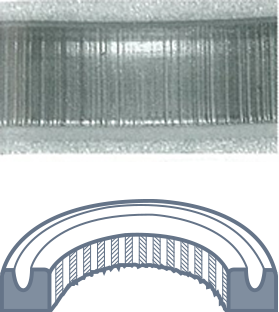

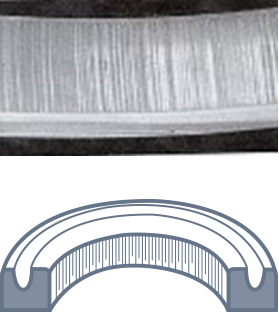

Operating with small stroke causes insufficient lubrication oil film. In the case of piston, change to SPG and SPGW. In the case of load, transform back up ring. Operation surface illumination is inappropriate (too high) Change to a recommended thickness. Operation width size is circumferentially different on the consecutive base. min width and max width are almost in symmetrical locations.

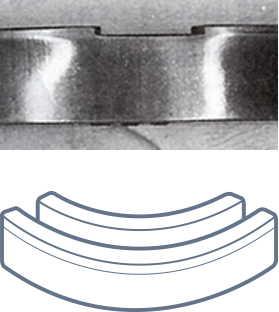

Offcenter between load cylinder bed, cylinder and piston bed Control attachment offcenter within the allowable packing limit. Circumferential part of operation lip is seriously worn out. abrasion (in line with lateral load)

Excessive lateral load causing abnormal abrasion in wearing( piston), and bearing(load) Change to more load-enduring wearing and bearing materials. Scratch Partial dinge at lip end

Damage by hanging on to nails, wires, etc. for storage or by external force causing local transformation Improve storage method. Insufficient chamfering on the opposite side during assembly Enlarge chamfering on the opposite side and smoothen to prevent flip over. Caused by driver, etc, during assembly Use assembly fixture. Scratch on operation part

Scratch on the opposite operation surface Inspect sufficiently before assembly. Caused by the flip over of the opposite chamfering part during assembly Perform chamfering according to standard table and soften to prevent flip over. Foreign substance embedded Clean well. Dinge

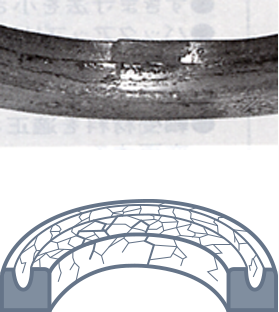

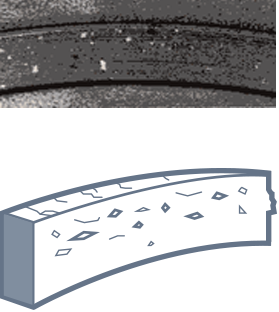

Small dinge hole on operation surface

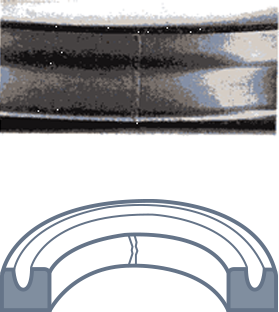

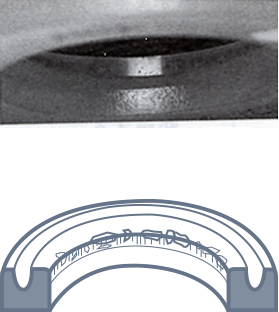

Poor cleaning to leave dust, cutting residue embedded Remove the foreign substances left on the machine. Foreign substance gets inside oil or oil oxidation porduct is embedded. Change to new oil. Damage Packing operation lip is damaged in circular form. (piston seal)

Excessive back pressure Change to OUHR. Change to SPG(SPGW). Crack from packing groove

Fatigue failure by frequent impulse pressure In the case of load, transform buffer ring. In the case of piston, change to SPG(SPGW). Operation at lower temperature to be destroyed Change to a rubber material packing with good cold-resistance. Overall operation lip damage

Packing material deterioration Change to a rubber material with good heat/oil-resistance. Oil deterioration Change to new oil. Damage in 1~2 parts of packing circumference

Packing was installed while being twisted. Assembly in inappropriate state of installation. Improve installation method and installation fixture. Burn damage

(燒損)Local burning of lip & groove parts to become carbonized or melted.

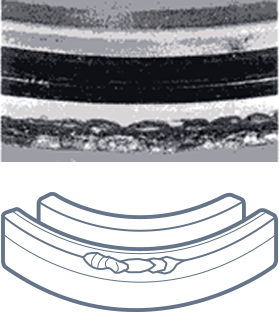

Burning damage by insulation compression by residual air Deflate hydraulic cylinder sufficiently before operation. Do not move to full stroke rapidly. In using Upacking, fill the pocket with grease and make air accumulation smaller. Stick out Operation heel is torn.

Excessive gap of leak Smaller the gap. Transform back up ring. Bearing abrasion is huge and Bearing gap increased. Change the bearing material to an appropriate material. Excessive pressure Transform back up ring and re-select packing. Transform back up ring. Fixation heel is torn.

Inappropriate equipment groove structure Modify chamfering part. Gap creation due to the insufficient pressure plate strength Improve pressure plate strength. back up ring is inappropriate Modify back up ring dimensions. Change back up ring material to a more precise one. Packing operation heal and back up ring sticks out.

Excessive gap of leak Smaller the gap size. Back up ring is inappropriate

- IRON RUBBER PACKING

-

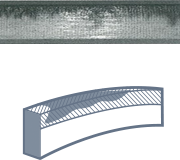

case status reason response Deterioration

(劣化)Lustrous, cracked on the surface or cracked if pressed with a finger

Excessive oil temperature increase Lower oil temperature or change to a heat-resistive material(fluorine rubber ). Inconsistence between oil and rubber material Check oil-resistance and change packing material, or operation oil. Oil deterioration Change to new oil. Poor rubber elasticity to just fall out

Excessive oil temperature increase Change to a rubber material with heat-resistance and oil-resistance. Inconsistence between oil and rubber material Check oil-resistance and change packing material or operation oil. Oil deterioration Change to new oil. Overall operation lip falls out

Excessive oil temperature increase Change to a heat-resistive rubber material. Inconsistence between oil and rubber material oil deterioration Check oil-resistance and change packing material, or operation oil. Change to new oil. Abrasion Operation surface is lustrous and worn on the mirror side.

In operation with small stroke, lubricate oil film formation is insufficient. In the case of piston, change to SPG. In the case of load, transform back up ring. All-time pressure application at least 3MPa In the case of piston, change to SPG. In the case of load, transform back up ring. Check system resistance and change the system structure to make low-pressure. Part of operation lip circumference is seriously worn out (in line with lateral load)

Excessive lateral load to cause wearing( piston), bearing(load) abnormal abrasion Change the wearing and bearing material to a more load-enduring one. Operation surface is worn.

In operation with small stroke, lubricate oil film formation is insufficient. Operation heating is huge and oil film is thin. In the case of sharp lip, change to R lip type. Change to a seal with excellent self-lubrication. In the case of load packing, add buffer ring. Scratch Ip end is partially torn or dented.

Hung on needles, wires, etc. during storage to receive external force Improve storage method. Enlarge the opposite-side chamfering and soften to prevent flip over. Tearing/denting by needle, drive, etc. during assembly Use assembly fixture Operation is scratched.

Scratch on the opposite-side operation surface Inspect sufficiently before assembly. Enlarge the opposite-side chamfering and soften to prevent flip over. Scratch by embedded foreign substances Clean well. Lip end is scratched.

Scratch by the flipped over opposite-side chamfering while assembly Soften the opposite-side surface according to dimension table. Damage Packing operation lip is damaged in circular form.

( piston seal)Excessive back pressure Change to OUHR. Change to SPG(SPGW). Crack from packing groove

Fatigue failure by frequent impulse pressure In the case of load, transform buffer ring. In the case of piston, change to SPG(SPGW). Stick out Operation heel is torn.

Excessive gap of leak Smaller the gap. Transform back up ring. Bearing abrasion is huge and Bearing gap increased. Change the bearing material to an appropriate material. Excessive pressure Transform back up ring and re-select packing. Transform back up ring. Small dent from operation surface heel to ilp end. Thin film-shaped spill part is attached on the heel part.

Excessive gap of leak Narrow the gap size. Transform back up ring. Pressure excessive Transform back up ring and re-select packing. Transform back up ring. Operation heel sticks out and is transformed. The overall color is changed into red.

Excessive gap of leak Narrow the gap size. Transform back up ring. Bearing abrasion is huge and bearing gap increases. Change the bearing material to an appropriate material. Pressure excessive Transform back up ring and re-select packing. Transform back up ring. The outside surface of Pure PTFE back up ring is torn and the packing thereof sticks out and is transformed.

Insufficient back up ring strength & poor abrasion-resistance Change the back up ring material to19YF or 80NP. Burn damage

(燒損)Packing groove is locally burned and carbonized.

Burn damage by insulation compression by remaining air Deflate Hydraulic cylinder sufficiently before start. Do not move to full stroke rapidly. In using Upacking, fill the pocket with grease and make air accumulation smaller. Transform Two points on outside surface are transformed and damaged.

Poor installation on groove

- Combination SEAL & SEAL-related products

-

Case Status Reason Response Deterioration

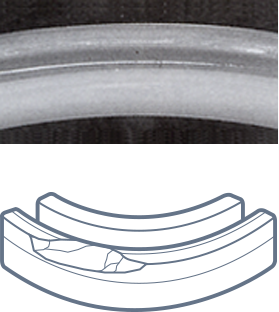

(劣化)Crack in back ring

Use at high temperature. Change to a more heat-resistive back ring material. Abrasion Part of seal circumference is seriously worn out

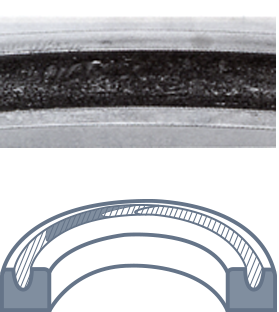

(in line with lateral load).Offcenter by abnormal abrasion in wearing and bearing caused by excessive lateral load Change to a more lateral load-enduring wearing and bearing material. The opposite-side operation surface is partially rough. Finish the illumination evenly (recommendate치:0.4~3.2μmRy) Scratch Rareflonring Operation is scratched.

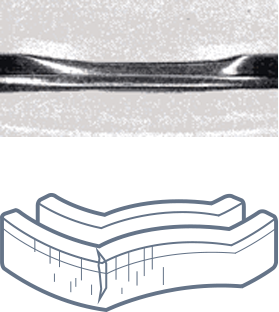

Scratch on the opposite-side operation surface Inspect sufficiently before assembly. Burr flip over on the opposite chamfering part while assembly Do chamfering on the opposite side according to standard table and soften to prevent burr flip over. Foreign substances such as metal power are embedded. Remove foreign substances. Design Contami seal (KZT) on both sides of packing. Stick out Seal operation has a film-shaped stick out.

Leak gap is huge. Pressure is high Narrow a leak gap. Change to a stronger material. Change to a back up ring-attached SPGW. Dent

(embedded

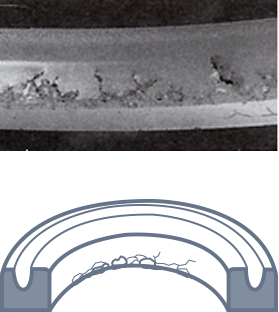

Foreign

Substance)Foreign substance is embedded in seal, back up ring.

Foreign substance exists inside oil and system. Clean well. Design Contami seal KZT) on both sides of packing. Piston and cylinder are scratched to create metal powder. Change the wearing and bearing material to a lateral load-enduring one. Stick out

(backup ring)Back up ring has a stick-out case.

Leak gap is huge. Pressure is high Narrow a leak gap. Change to a stronger back up ring material. Burn damage

(燒損)One side of wearing is carbonized.

Burn damage by insulation compression by remaining air Narrow a leak gap. Change to a stronger back up ring material.

Dear visitors Thank you for coming to the E-mos homepage. The company produces sealing-related rubber products used for semiconductors, LCD-related equipment, industrial devices, etc.

About Company

Products

Technology Info

R&D Center

Customer Support

32, Hakchon-ro, Yanagji-myeon, Cheoin-gu,

Yongin-si, Gyeonggi-do, ROK

TEL : 031-322-3311 | FAX : 031-322-3405

E-mail : jjk2002@e-mos.kr

Copyright ⓒ MOS 2015 All rights reserved.