Curing joint products

Curing joint products

MOS can manufacture any customized circular type of o-rings and packings if the customer knows the cross section diameter for o-ring and the cross sectional dimension for packing, for which MOS is able to produce cost-effective products with one joint mould.

- Product Overview

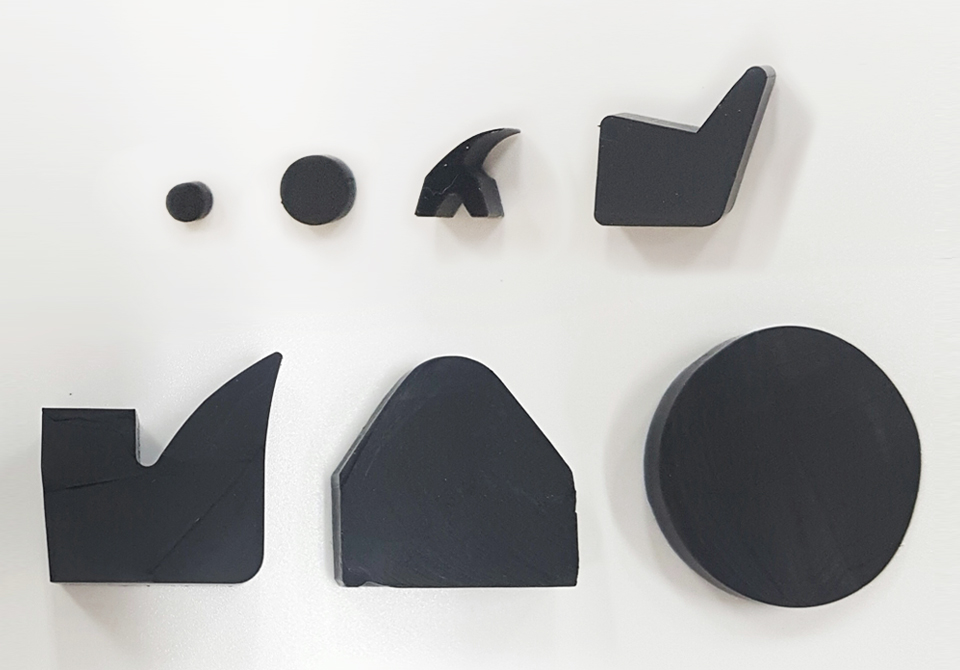

- In general, non-standard large-sized o-rings and/or packings have been mostly manufactured by the processing that consecutively produce semifinished products in the way of extrusion moulding after that, cutting them by the customized size and then glue the pieces with an adhesive in accordance with customer requirements. In this way of processing, the gluing joint has caused lots of sealing problems due to an inferior quality of strength, heat-resistance, oil & chemical-resistance etc. However, all curing joint products both standard size and non-standard size manufactured by MOS have excellent performance, because MOS does not use any adhesive for jointing, but has entirely produced those products in the way of the compressed press moulding that is original forming procedure of rubber.

- Product Feature

- MOS can manufacture any customized circular type of o-rings and packings if the customer knows the cross section diameter for o-ring and the cross sectional dimension for packing, for which MOS is able to produce cost-effective products with one joint mould. MOS is producing all curing joint products in the way of compressed press moulding processing instead of extrusion moulding so that the product has much higher durability and no leaking risk from hardening phenomenon occurred by chemical reaction into product and adhesive.

- Product Selection

- With the cross section shape of o-rings, packings and rubber washers etc, MOS can produce any customized product that has internal diameter, and is also able to manufacture almost all the rubber products of NBR, EPDM, Silicone and perfluoro etc.