For CMP equipment

- Membrane Overview

- A key part attached on the back of semiconductor wafer inside CMP(Chemical mechanical polishing) device to absorb semiconductor wafer in the semiconductor wafer polishing process. The company successfully domesticated its production thanks to the recognized technological capacity.

- Membrane Features

- As membrane contacts semiconductor wafer directly, it has no surface scratch, foreign substance, bubble and other defect at all. For its direct relationship with polishing, membrane thickness should be maintained constantly within ±0.1mm difference.

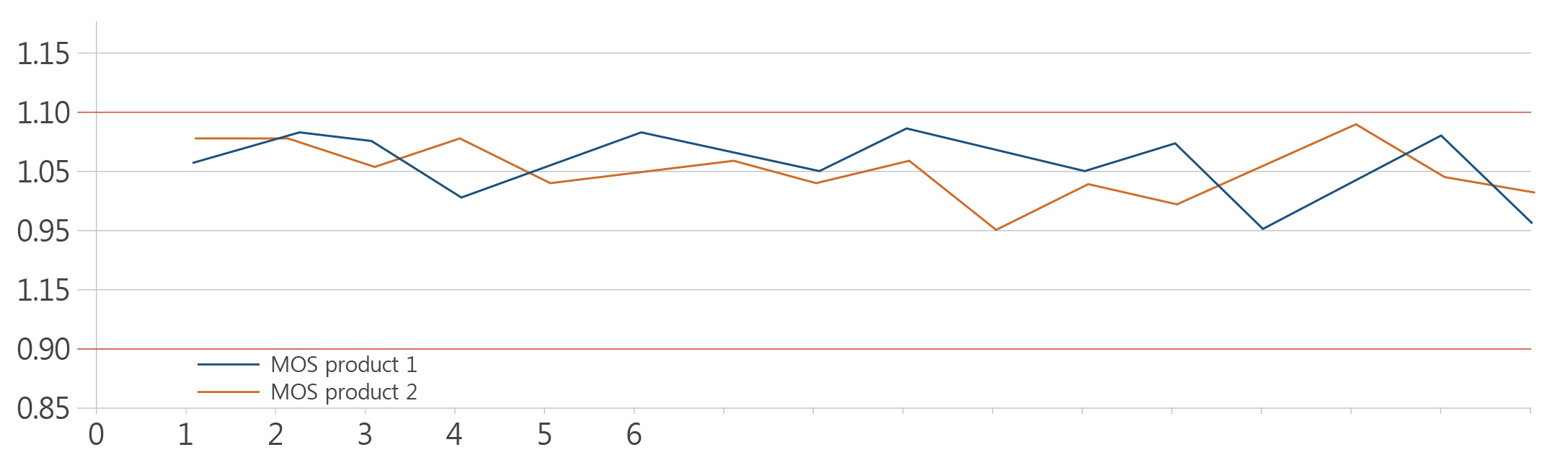

- MOS product thickness management

-

| Product | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | max | min | average | R | standard deviation |

| MOS product1 | 1.05 | 1.09 | 1.06 | 1.08 | 1.05 | 1.07 | 1.05 | 1.04 | 1.07 | 1.05 | 1.04 | 1.06 | 1.00 | 1.03 | 1.07 | 1.00 | 1.09 | 1.00 | 1.051 | 0.09 | 0.025 |

| MOS product2 | 1.06 | 1.07 | 1.05 | 1.07 | 1.03 | 1.03 | 1.04 | 1.03 | 1.05 | 0.99 | 1.03 | 1.01 | 1.04 | 1.07 | 1.03 | 1.02 | 1.07 | 0.99 | 1.039 | 0.08 | 0.022 |

Graph comparing MOS product 1 and MOS product 2

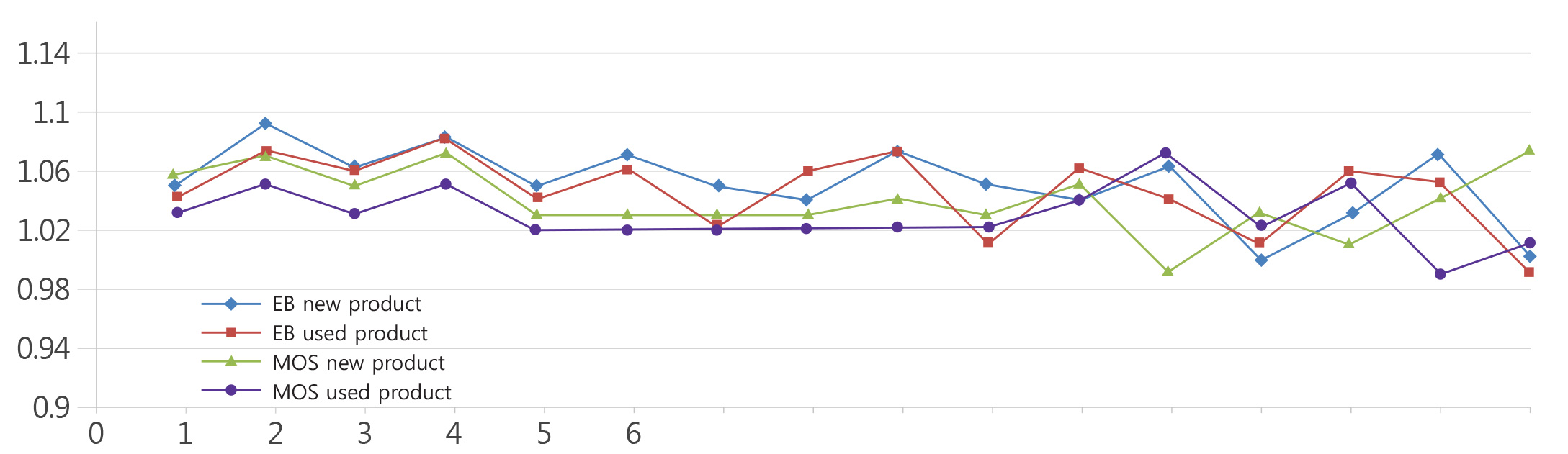

Use before and after comparison chart of foreign products and MOS products

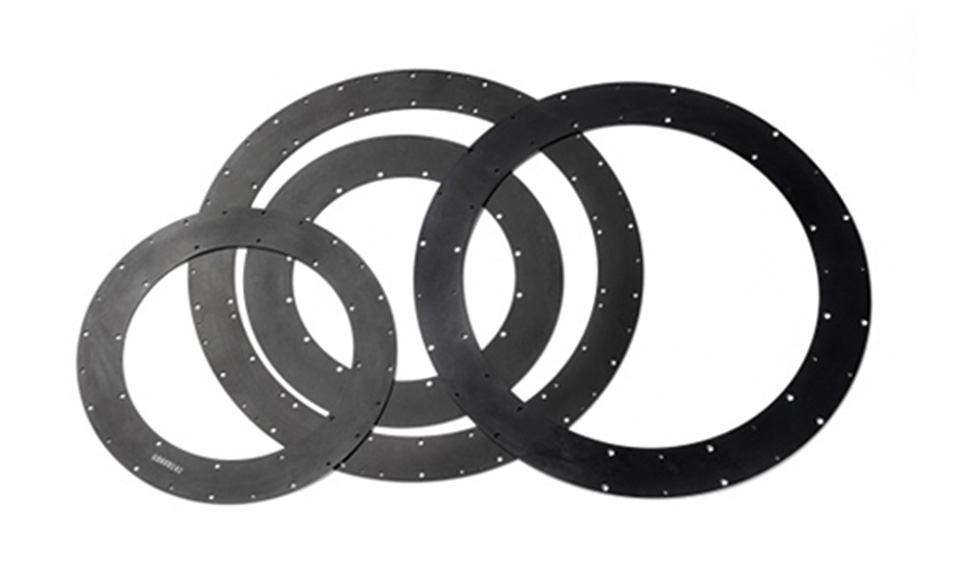

- CMP Equipment Types

- Membrane types are differentiated according to each CMP equipment head and produced in two different sizes of 200mmm and 300mmm. The 300mm size is used mostly in line with semiconductor development towards high-integration and yield enhancement. The 200mm size is produced with two materials of EPDM and silicon. The 300mm is made of the silicon material.

300mm MEMBRANE

200mm MEMBRANE

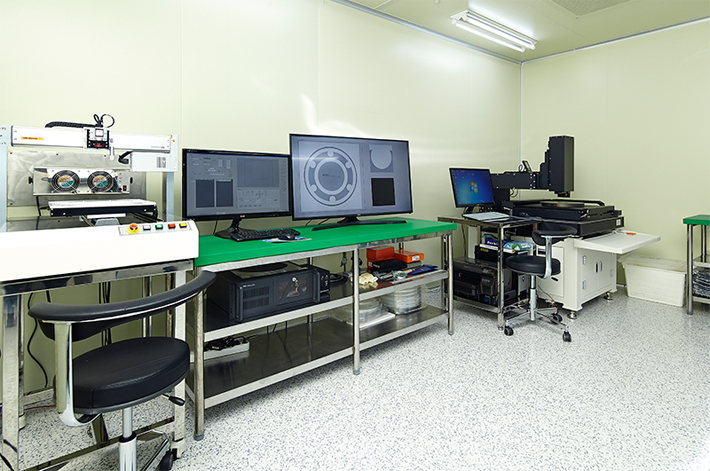

- MOS Quality Management

- The specifications and debris of all products produced by utilizing a proprietary vision measuring and debris checker and automatic inspection. From customers through this exhaustive inspection system "error rate zero" is being conducted in a thorough quality control system of the target.

- Other CMP products

-

-

Flexure A kind of gasket mounted on CMP equipment head to seal off the product from chemicals or impurities such as slurry during the polishing.

-

Air Bag A part used for air float-type equipment among the CMP equipment to charge air into the upper part of the head and pressurize wafer

-

Idler & Washer Roller Idler Roller locates between Washer to support wafer during CMP equipment wafer washing. Washer Roller plays a role of wafer rotation driving during washing. ※ If ROLLER(IDLER & WASHER) has a partial disposition and wears easily, it could cause hunting.

-

Rolling Seal Mounted inside the CMP equipment head to add pressure and seal constantly moving part ※ Durability is required to endure continuously repeated movements.

-